| Item | Electrolysis | Influent | 1st Aerobic | 1st Anaerobic | 2nd Aerobic | 2nd Anaerobic | 3차 Aerobic | 3차 Anaerobic | Precipitation | Effluent |

|---|---|---|---|---|---|---|---|---|---|---|

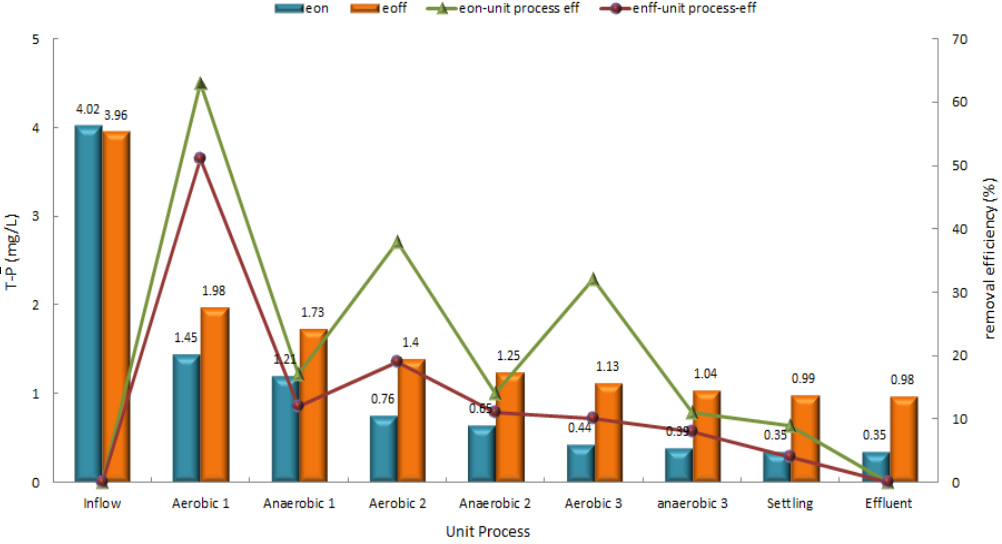

| T-P Density (mg/ℓ) | On | 4.02 | 1.46 | 1.21 | 0.76 | 0.65 | 0.44 | 0.39 | 0.35 | 0.35 |

| Off | 3.96 | 1.98 | 1.73 | 1.40 | 1.25 | 1.13 | 1.04 | 0.99 | 0.98 | |

| T-P Treatment efficiency(%) | On | 0.00 | 63.58 | 69.80 | 81.21 | 83.82 | 89.17 | 90.32 | 91.21 | 91.34 |

| Off | 0.00 | 50.15 | 56.45 | 64.71 | 68.48 | 71.59 | 73.71 | 75.06 | 75.32 | |

| Treatment efficiency by process (%) | On | 0.00 | 63.58 | 17.09 | 37.78 | 13.87 | 33.08 | 10.65 | 9.19 | 1.47 |

| Off | 0.00 | 50.15 | 12.64 | 18.97 | 10.67 | 9.87 | 7.46 | 5.12 | 1.07 |

| Item | Iron electrode (Purity 98%) | Fecl3(37%) | PAC(17%) |

|---|---|---|---|

| Facility capacity (m3/day) | 60m3/day | ||

| Targer removed(T-P) | 3.5mg/ℓ | ||

| Dosage | 185g/day | 8.86kg/day | 12.12kg/day |

| Yearly dosage(kg) | 67kg/year | 3,233.9kg/year | 4,423.8kg/year |

| Processing cost (won/kg) | 950won/kg (Iron 80%use) | 280won/kg | 360won/kg |

| Electricity cost | 84,000won/yr+0.75kw×6h/day×365/yr×65won/kw | ||

| Annual treatment cost | 101,668원/yr | 905,492won/yr | 1,592,568won/yr |